In a world where technology continues to advance at an unprecedented rate, the demand for flexible and lightweight electronic devices has never been greater. From wearable tech to bendable screens, the possibilities seem endless. One promising technology in this field is thin-film electronics, offering a new approach to chip design that is both flexible and efficient. In this article, we will explore the feasibility of using thin-film electronics for flexible chip design, examining its potential impact on the future of electronic devices.

Innovative applications of thin-film electronics in flexible chip design

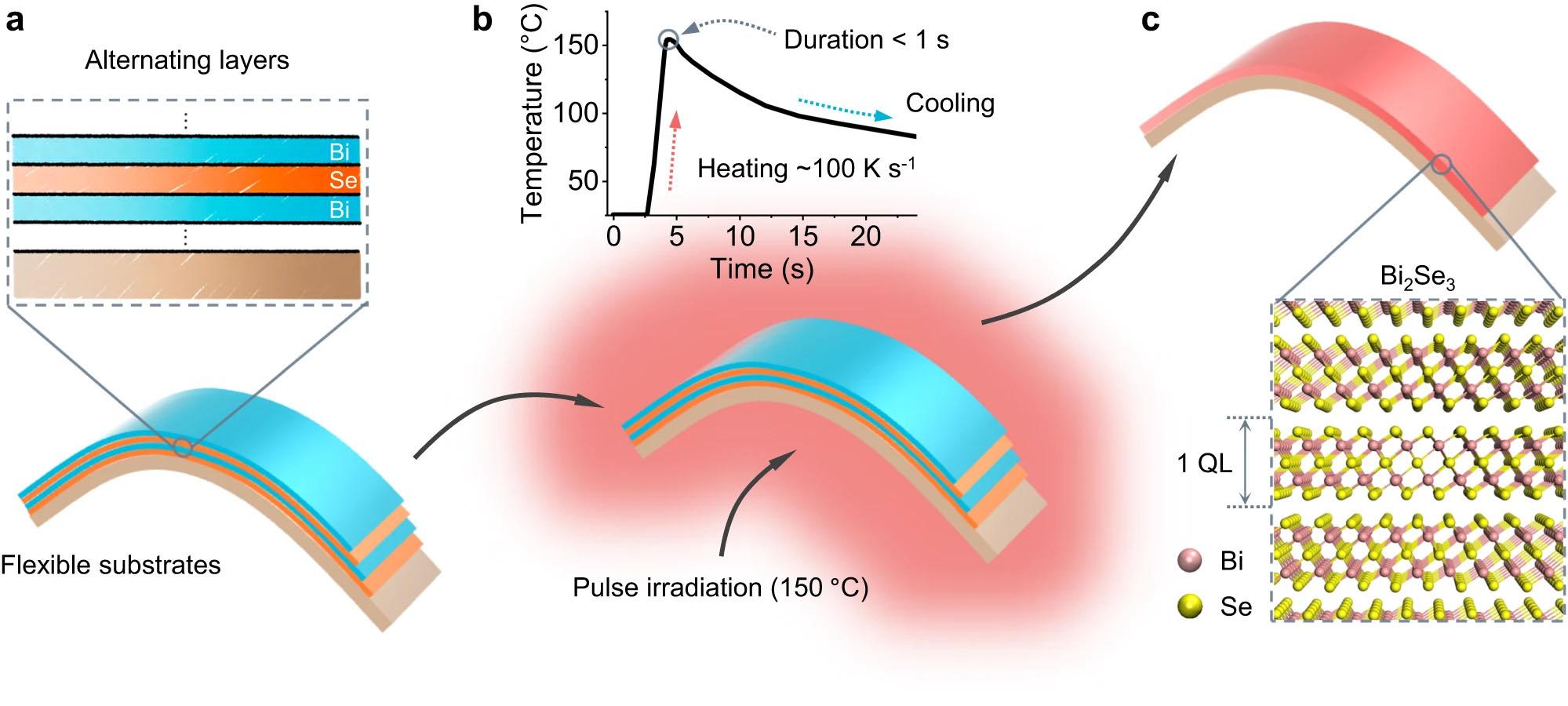

Thin-film electronics have opened up new possibilities in the realm of flexible chip design, allowing for innovative applications that were previously unattainable. By utilizing thin-film technology, chips can now be made more flexible, durable, and lightweight, making them ideal for a wide range of applications in various industries.

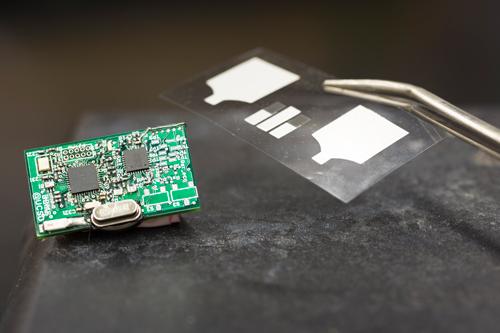

One of the key advantages of thin-film electronics in flexible chip design is their ability to conform to non-traditional shapes and surfaces, enabling the creation of unique and customizable products. Additionally, thin-film chips are more cost-effective to produce than traditional silicon chips, making them an attractive option for companies looking to streamline their manufacturing processes. Overall, the feasibility of using thin-film electronics in flexible chip design is proving to be a game-changer in the world of technology.

Advantages and challenges of incorporating thin-film electronics in chip design

One of the key advantages of incorporating thin-film electronics in chip design is the flexibility it offers. Thin-film electronics allow for the creation of bendable and stretchable chips, making them ideal for applications where traditional rigid chips would not be suitable. This flexibility opens up a whole new range of possibilities for the design of electronic devices.

However, there are also some challenges that come with using thin-film electronics in chip design. One major challenge is the durability of the thin-film materials. Thin-film electronics are more prone to wear and tear compared to traditional silicon chips, which could impact the longevity of devices incorporating these technologies. Additionally, integrating thin-film electronics into existing chip design processes can be complex and may require significant adjustments to manufacturing processes.

Potential breakthroughs in flexible chip technology with thin-film electronics

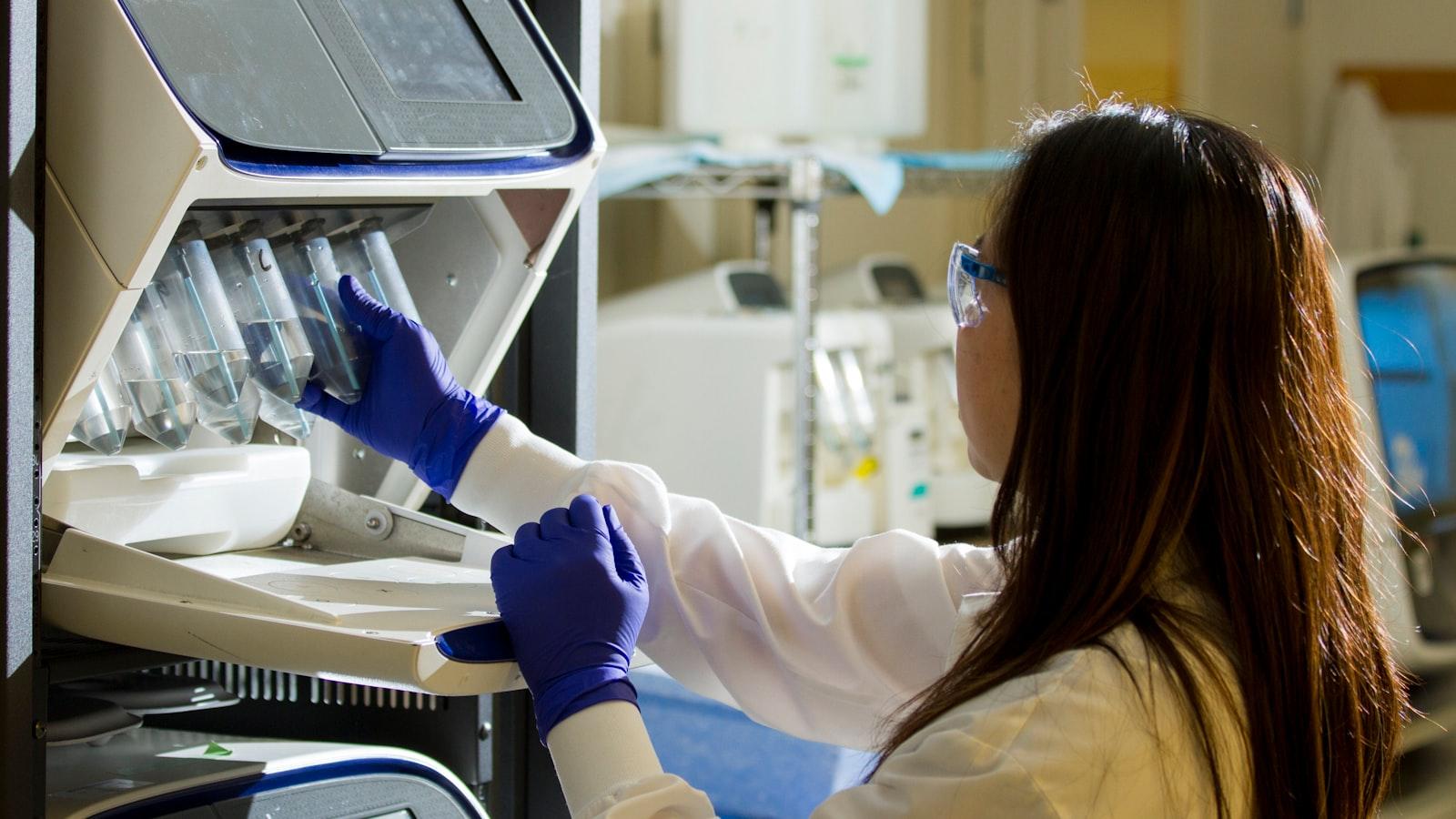

Thin-film electronics have been at the forefront of research for flexible chip technology, promising a new era of innovation in electronic devices. These thin and lightweight components are revolutionizing the way chips are designed and manufactured, opening up a world of possibilities for flexible, bendable, and even wearable electronics. The feasibility of integrating thin-film electronics into chip design is becoming increasingly apparent, with potential breakthroughs on the horizon.

With flexible chip technology, the possibilities are endless. Imagine a world where devices can seamlessly adapt to the contours of our bodies, making them more comfortable and convenient to use. Thin-film electronics offer the flexibility and durability needed to create next-generation chips that can withstand bending and twisting without sacrificing performance. The potential for groundbreaking advancements in wearable technology, medical devices, and beyond is truly exciting.

Recommendations for optimizing performance and functionality of thin-film electronics in chip design

When designing flexible chips using thin-film electronics, it is crucial to consider certain recommendations to optimize performance and functionality. One key recommendation is to carefully select materials that are both flexible and durable, such as amorphous silicon or organic semiconductors. These materials are essential for ensuring the chip’s longevity and resistance to bending and stretching.

Another recommendation is to design the chip layout with flexibility in mind, allowing for different configurations to accommodate varying use cases. This approach can enhance the chip’s adaptability and versatility, making it suitable for a wide range of applications. Additionally, utilizing advanced manufacturing techniques like roll-to-roll processing can enhance production efficiency and scalability, making it easier to mass-produce flexible chips with thin-film electronics.

The Conclusion

In conclusion, the feasibility of thin-film electronics for flexible chip design opens up a world of possibilities for the future of technology. With advances in materials and manufacturing techniques, the potential for creating flexible, lightweight, and powerful electronic devices is within reach. As researchers and engineers continue to push the boundaries of innovation, we can look forward to a future where electronics seamlessly integrate into our everyday lives in ways we never thought possible. The potential for thin-film electronics is truly limitless, and the journey towards realizing this potential is just beginning. So, let’s stay curious, stay inspired, and keep pushing the boundaries of what is possible in the world of flexible chip design. Exciting times lie ahead!